A smooth quiet poultry production line will ensure live birds remain calm, and work is hassle free. Daily or routine slaughterhouse maintenance must be performed by the operators. It includes slaughtering equipment cleaning, refuelling, adjustment, checking lubrication, noise, oil leakage, safety accessories and wear pattern etc. Maintain regular maintenance records and replace individual parts when necessary.

1. Machinery Maintenance

Be very careful to avoid water near the assembly line motors. This will cause damage to the motor and affect its use. It will also shorten the service life of slaughtering equipment. Our slaughterhouse conveyor lines are usually designed for / supplied with SEW motors. For specific detailed motor machinery maintenance please see the SEW motor maintenance guide on their website.

Given that water is frequently used, and blood & chicken meat contains acidic fats, there’s an inherent risk of rust. Therefore, it’s crucial to exercise proper care during and after each use. With regards to circular saw blades:

- Post-use (i.e. after each shift), the blade should be thoroughly cleaned with water to remove any chicken blood and residue.

- After rinsing, it must be dried completely, either with compressed air or a clean, dry cloth.

- After final drying, apply a thin layer of high-quality cooking oil to the blade.

- Repeat this oil application before each use to prevent rust accumulation.

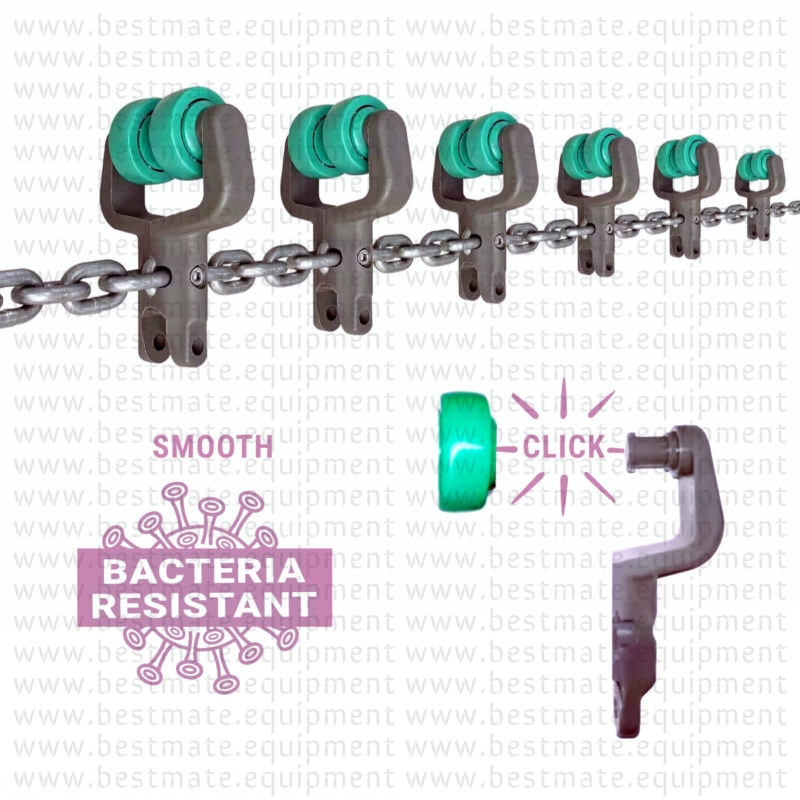

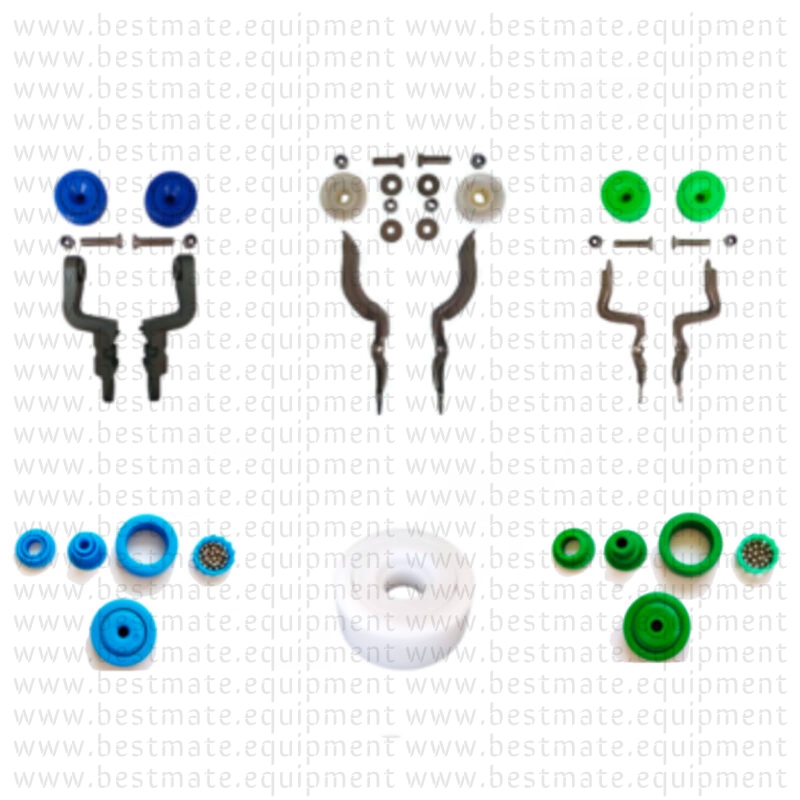

2. Chain Maintenance

Regular chain maintenance is crucial for optimal operation of the poultry line to ensure smooth and efficient abattoir tasks. Inspect the chains regularly for any signs of wear, corrosion, or loose links. Lubricate the chains as recommended by the manufacturer to ensure smooth movement and prevent premature damage. Neglecting chain maintenance can lead to disruptions in the slaughtering process and potential equipment failure.

Weekly maintenance:

This maintenance includes inspecting the chains for any signs of wear or damage, lubricating them to prevent friction, and adjusting their tension if necessary. It is also important to check for any loose or missing bolts, and to clean the chains to remove any debris or buildup. Also check connection links to ensure they are secure. Galvanized links are less prone to stretching.

By conducting these weekly maintenance tasks, operators can minimize downtime and maximize the lifespan of the assembly line chains. BestMate can supply line tensioners for adjusting elevated lines.

To reduce rust, use galvanized chains or even better, for optimum hygiene, use 304-grade stainless steel chains and SS304 links. We have a range of sizes available.

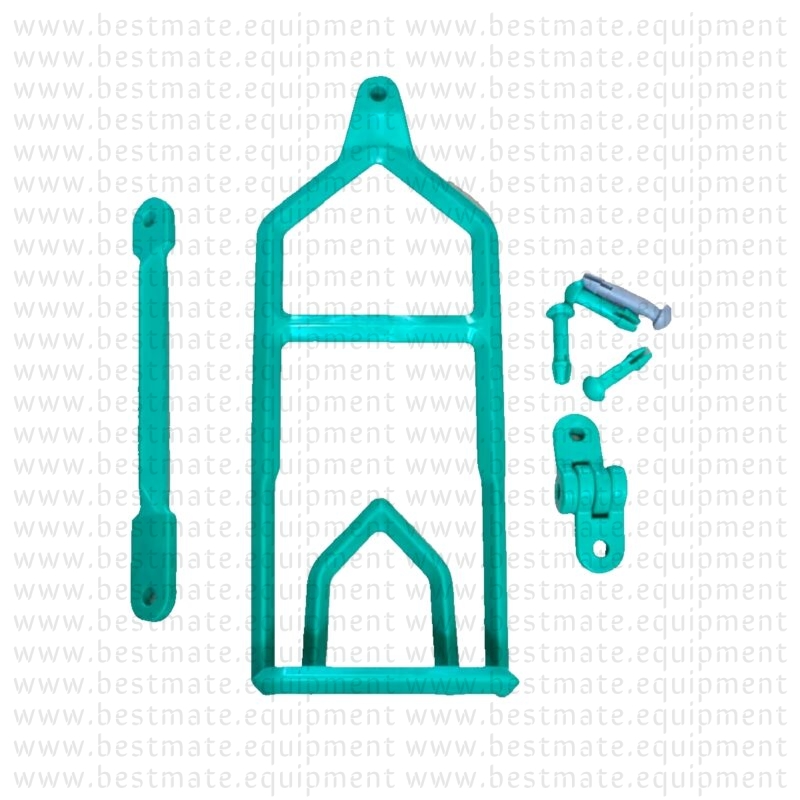

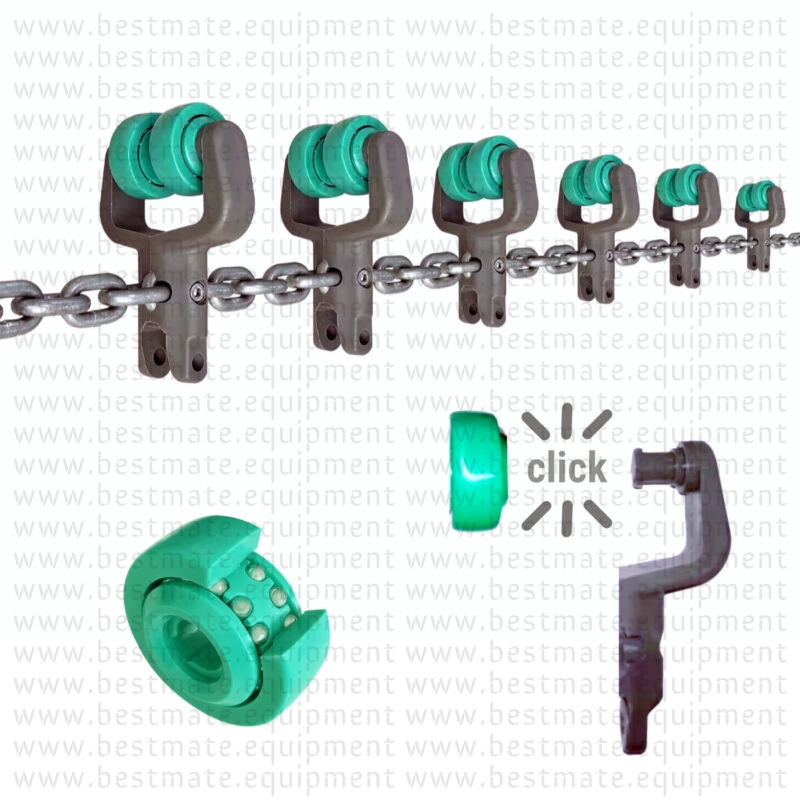

Lightweight plastic components (trolley and shackle assemblies) can reduce the strain on the elevated line, and make cleaning easier. For instance, we can supply smooth plastic yokes with click-on wheels to minimise weight and corrosion (less bolts, and less crevices where bacteria could get trapped).

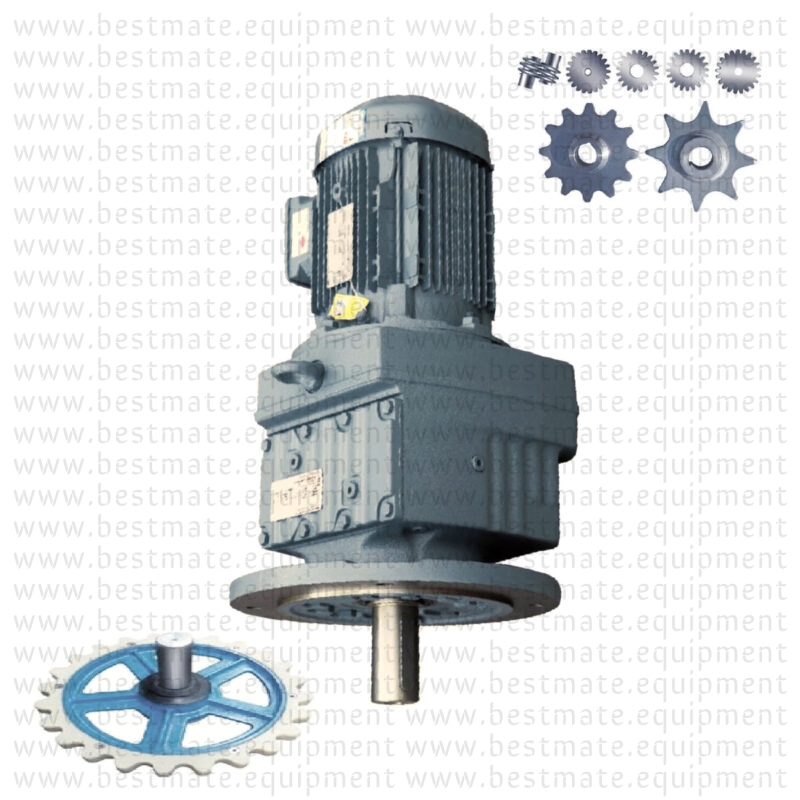

3. Head Reducer Maintenance

About three months after starting use, drain the oil in the gearbox. Use diesel or gasoline to drain the oil in the gearbox, and immediately put new lubricating oil into the middle of the observation window. From then on, it is enough to change the lubricant once a year.

Too much lubricating oil may cause the reducer to overheat, and excessive motor load may cause the motor protection switch to trip. Not enough lubricating oil may cause the reducer to heat up, increase noise, and may cause the reducer to seize and fail.

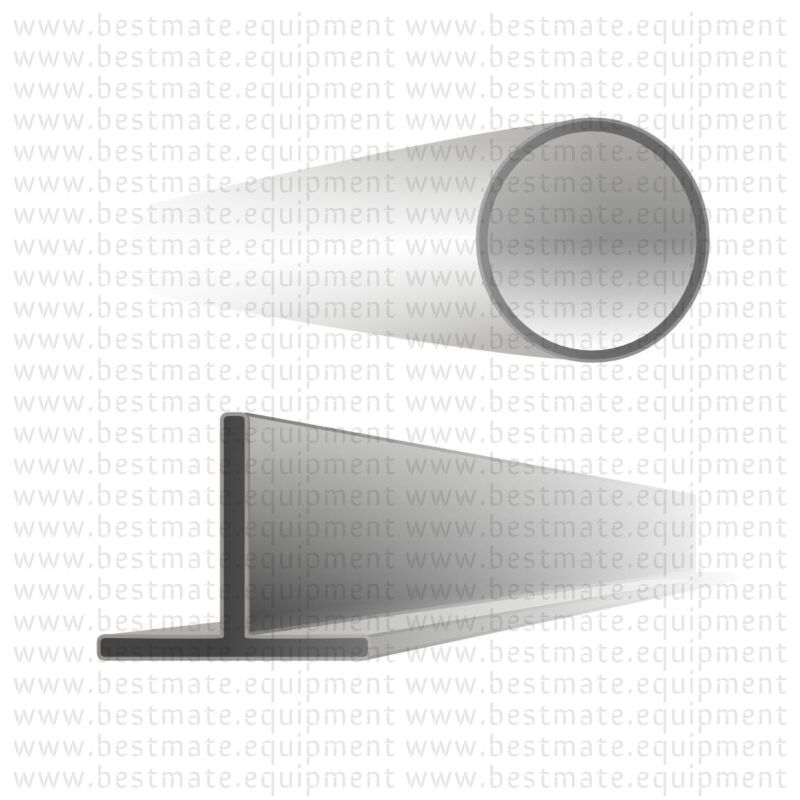

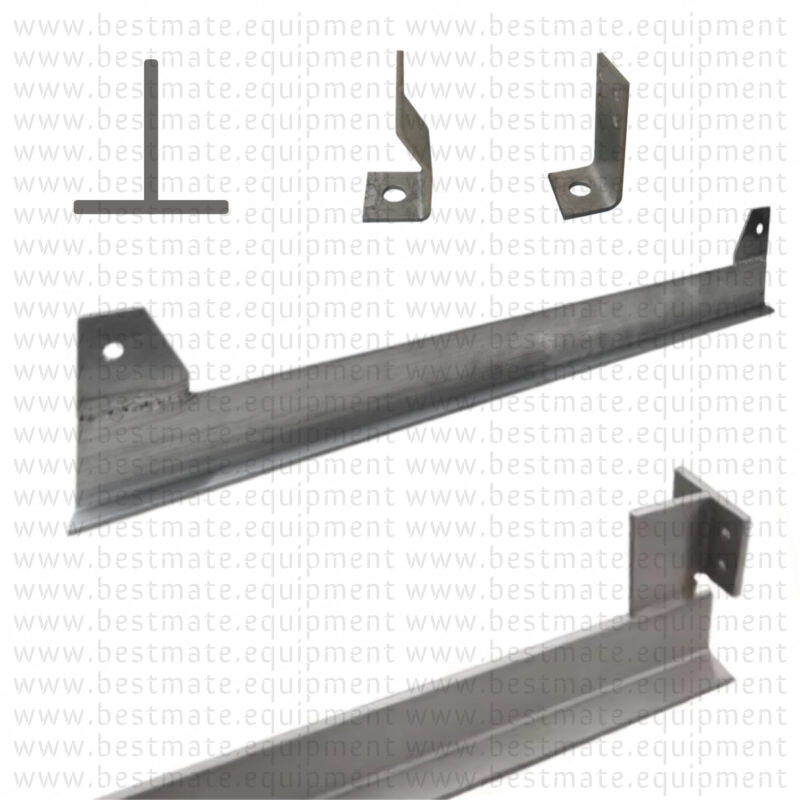

4. Overhead Conveyor Tracks

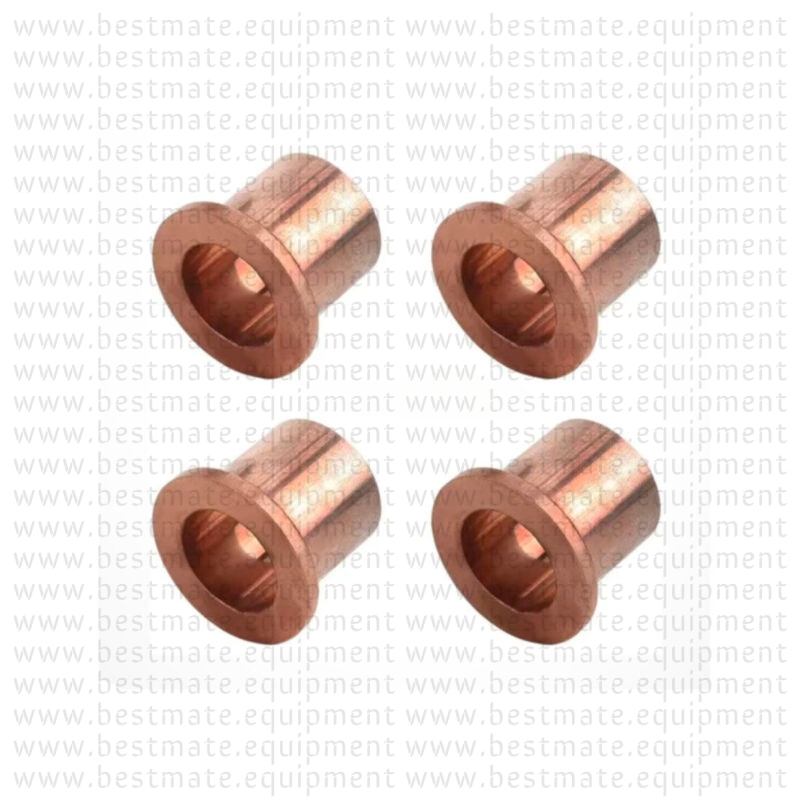

Regular check welds, joins and lug connecting bolts for smooth, frictionless operation of the assembly line.

Listen out for unusual noises, like squeaks or rattles which may indicate loose bolts or seized bearings.

5. Abattoir Maintenance Checklist

After primary maintenance is complete, slaughtering equipment must meet the following requirements:

- equipment is clean & shiny

- oil path is unobstructed

- oil flow is good

- operation is flexible

- operation is normal

- safety protection and indicating instruments are complete and reliable

- emergency stop buttons are working properly.